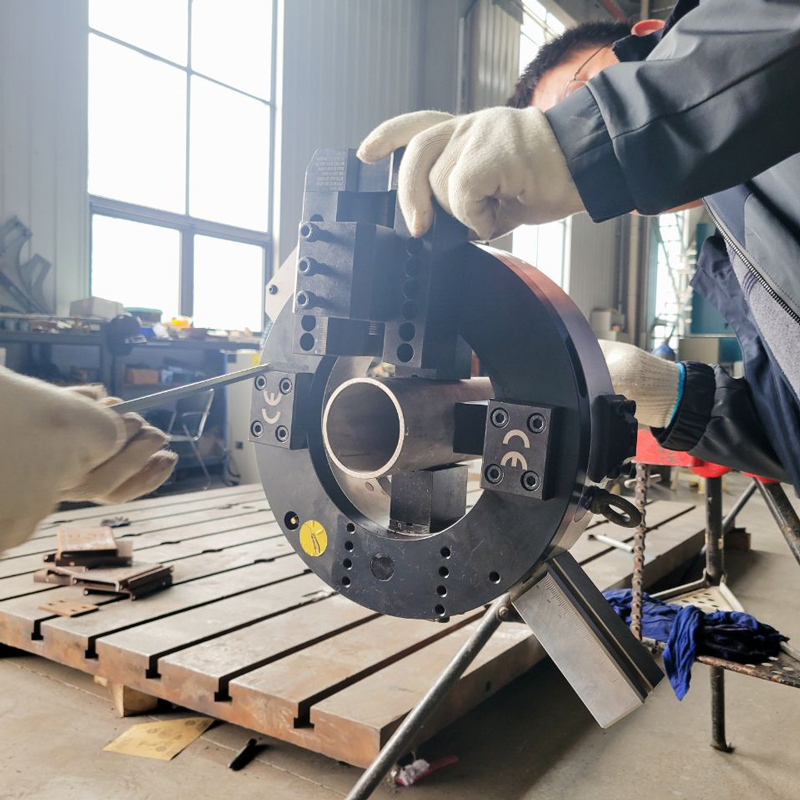

External card type electric cutting and beveling machine

Product Details Column externally mounted electric pipe cutting and beveling machine is a lightweight cutting and beveling equipment, high speed, low energy consumption, motor-driven, with a relatively light weight, small radial space, easy to use, etc. This product is widely used in the p...

Description

marker

Product Details

Column externally mounted electric pipe cutting and beveling machine is a lightweight cutting and beveling equipment, high speed, low energy consumption, motor-driven, with a relatively light weight, small radial space, easy to use, etc. This product is widely used in the petroleum, chemical, natural gas, food, boiler, ship, pharmaceutical, nuclear power, stadium construction industry pipeline installation projects and repair operations, such as the West-to-East Natural Gas Transmission Project.

Selection of technical parameters

| Motorized Model | Machining range (ID.mm) | Cutting Bevel Wall Thickness (mm) | Rotating speed of cutter r/min | |

| single-knife | folding knife | |||

| ISD-90 | Φ10-90 | ≤25 | ≤50 | 0~34 |

| ISD-168 | Φ25-168 | ≤25 | ≤50 | 0~24 |

| ISD-219 | Φ50-219 | ≤25 | ≤75 | 0~23 |

| ISD-273 | Φ114-273 | ≤25 | ≤75 | 0~23 |

| ISD-323 | Φ168-323 | ≤25 | ≤80 | 0~23 |

| ISD-355 | Φ219-355 | ≤25 | ≤80 | 0~23 |

| ISD-406 | Φ254-406 | ≤25 | ≤80 | 0~22 |

| ISD-457 | Φ323-457 | ≤25 | ≤80 | 0~20 |

| ISD-508 | Φ355-508 | ≤25 | ≤80 | 0~20 |

| ISD-559 | Φ406-559 | ≤25 | ≤80 | 0~14 |

| ISD-610 | Φ457-610 | ≤25 | ≤80 | 0~14 |

| ISD-762 | Φ610-762 | ≤25 | ≤80 | 0~13 |

| ISD-914 | Φ762-914 | ≤25 | ≤80 | 0~11 |

Product Features

1. Mounted on the outer wall of the pipe, multi-point clamping.

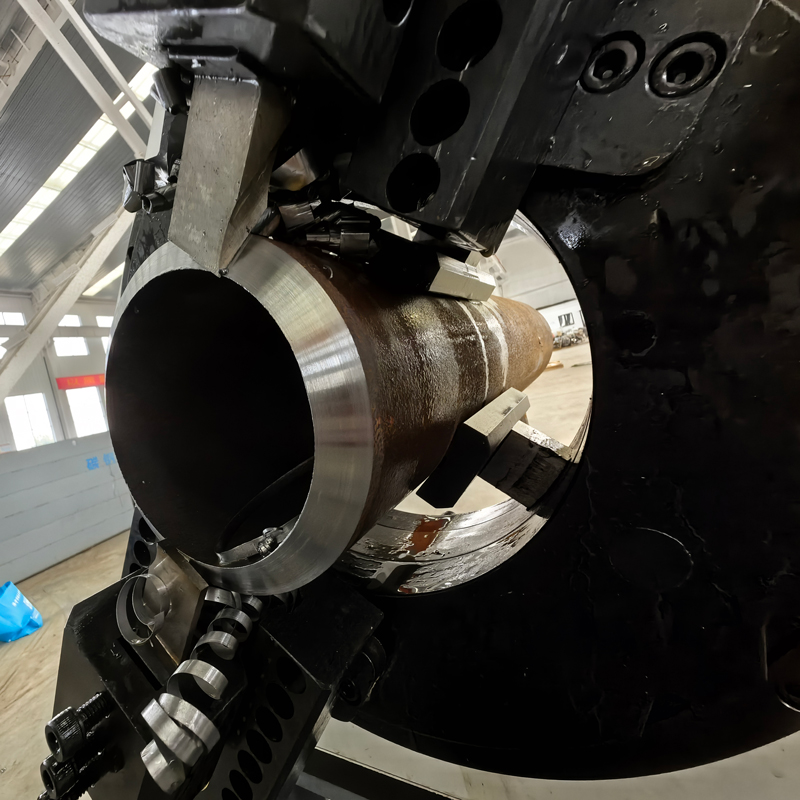

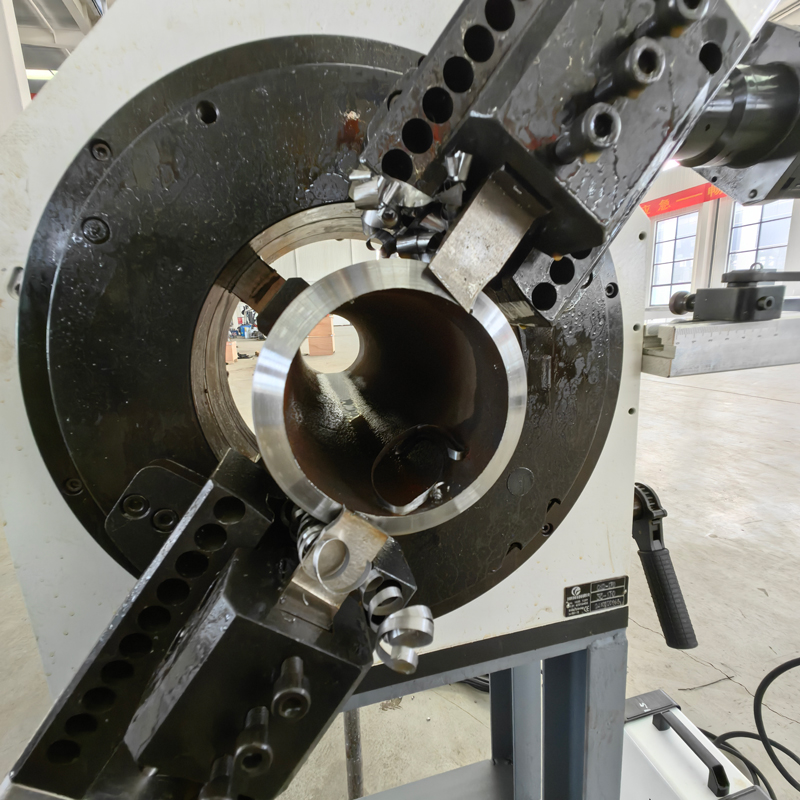

2. One clamping, cutting and beveling can be carried out at the same time.

3. Cold cutting method, without changing the pipe material.

4. Automatic knife feeding, no need for manual adjustment.

5. The body is a folio ring structure, which can be divided into two flaps and installed in various positions of the pipeline, which is quick and convenient.

6. Applicable to various grades of carbon steel, stainless steel, alloy steel and other metal pipe cutting bevel processing.

7. can be processed according to customer requirements of different forms of beveling, “U” single “V” double “V” and “J” type.

8. Wider processing range: pipe diameter from 10mm to 2500mm, can be selected for processing.

9. Free selection according to the different specifications of pipeline diameter.

10. Rapid cutting and beveling process for various types and specifications of pipelines, pressure vessels and steam generators.

11. Widely used in pipeline installation projects and repair operations in petroleum, chemical, natural gas, food, boiler, pharmaceutical, nuclear power, arena construction and other industries, such as the West-East Gas Transmission Project.

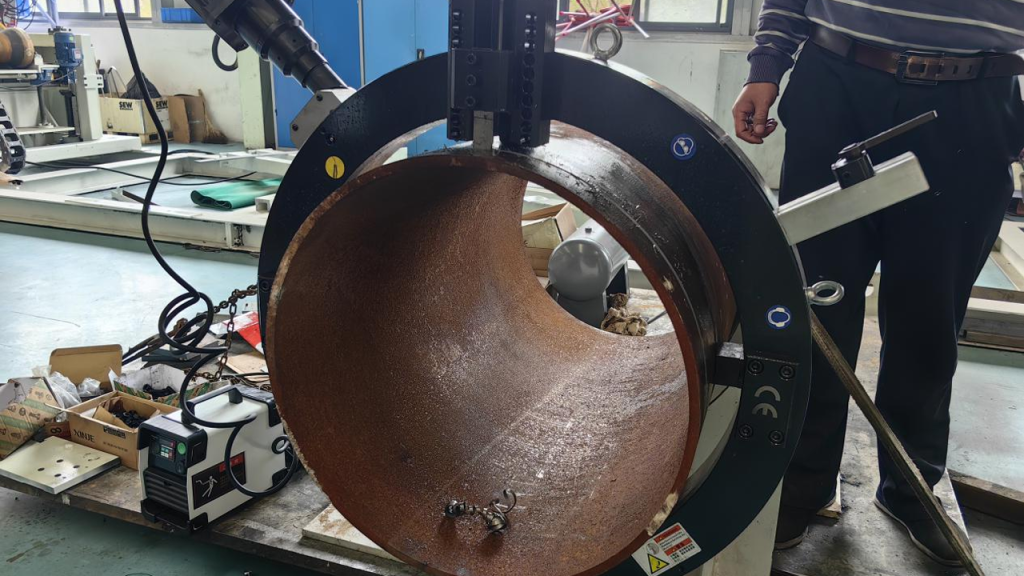

Portable tabletop pipe cutting and beveling machine

D series mobile pipe cutting and beveling machine, for small and medium batch pipe prefabrication processing research and development of cutting and beveling machine, is a mobile economic pipe cutting and beveling machine tools. It can be used for pipe prefabrication processing in workshop, and it is also convenient for pipe cutting and beveling processing in field construction site. The host can be fixed on the site of the existing operating table, can also be equipped with our trolley-type mobile worktable, its design is innovative, powerful, easy to operate, very wide range of applications. It is a combination of portable and fixed pipe cutting and beveling equipment functions and applications, making fast installation and fast cutting and repeatable cutting possible, with other accessories, it can also become a pipe cutting machine or pipe welding equipment, a variety of uses make the best use of it.

Technical parameters

| Model Specification | Processing range ODmm | Bevelwall thickness mm | Cutter speed rpm | Motor power KW | |

| Electrically operated | numerical control | ||||

| D4 | D4A | Φ20-120 | ≤20 | 0-33 | 1.43 |

| D6 | D6A | Φ35-170 | ≤30 | 0-23 | 1.43 |

| D9 | D9A | Φ76-220 | ≤30 | 0-18 | 1.43 |

| D13 | D13A | Φ168-320 | ≤30 | 0-14 | 1.43 |

| D16 | D16A | Φ273-420 | ≤30 | 0-14 | 1.43 |

| D20 | D20A | Φ377-520 | ≤30 | 0-13 | 2 |

| D24 | D24A | Φ457-620 | ≤30 | 0-13 | 2 |

| D30 | D30A | Φ559-720 | ≤30 | 0-13 | 2 |

Product Features

1. Complete cold cutting method, without changing the tube material.

2. One clamping, cutting and beveling at the same time.

3. Multi-point synchronized clamping, more efficient pipe installation.

4. Automatic centering mechanical clamping system, high installation precision.

5. Automatic knife feeding, speed adjustable.

6. Wider processing range: from 20-720mm can be selected processing.

7. Can be processed U-type, V-type, J-type and double V-type and composite types of various forms of bevel.

8. One-piece casting body, equipment rigidity and strength is better, making high-speed cutting possible.

9. The main body and saw blade type pipe cutter through the match, replace the knife frame and power head can be transformed into a pipe cutter.

10. Optional pipe welding gun and other accessories, can be line into a set of all-round automatic pipe welding equipment.

11. CNC type optional Delta servo motor, PLC control system operation, cutting parameters can be preset.