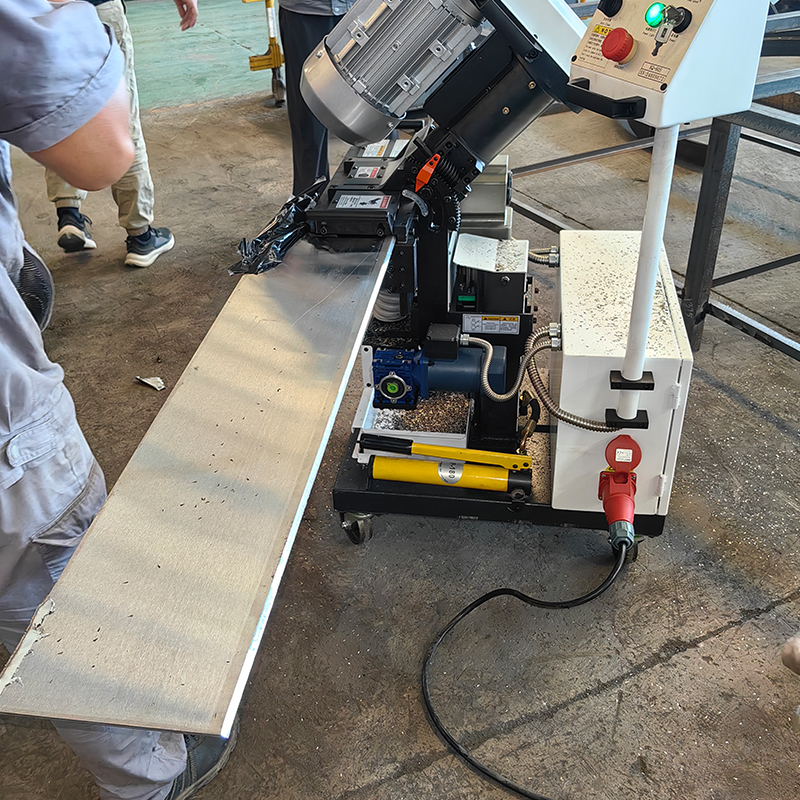

KQ-60S Economical Flatbed Edge Milling Machine

Specification Model: KQ-60S

Total power:4520W

Spindle speed:1050r/min

Feed speed:0~1500mm/min

Clamping plate thickness: 4~60mm

Bevelling angle: 0~60°

Bevel width: 0~45mm

Description

marker

Product Details

KQ-60S edge milling machine, processing bevel style: V / Y-type bevel, X / K-type bevel (need to flip the workpiece), 0 degrees side milling. Can process carbon steel Q235, Q345, manganese steel, aluminum alloy, copper, stainless steel and other metal materials, finish to Ra3.2~6.3. Mainly used for plate beveling and milling operations, in the steel structure, pressure vessels, bridge manufacturing, construction machinery, shipbuilding and other fields of beveling operations have been widely used.

| KQ-60S Technical Parameters | |

| power supply:AC380V 50Hz | Bevel angle:0°-60° |

| total power:4520W | Single Bevel Width:0-15mm |

| Motor speed:1050r/min | Bevel width:0-45mm |

| Feed rate:0-1500mm/min | Diameter of cutter plate:63mm |

| Clamping plate thickness:4-60mm | Table height:680-700mm |

| Clamping plate width:≥60mm | Walking Floor Area:800×800mm |

| Processing plate length:≥300mm | net weight:270Kg |

Advantages of KQ-60S economic flatbed edge milling machine

1. Small size, light weight, easy to move, simple operation.

2. Cold cutting without deformation, smooth bevel without oxidation, bevel finish 3.2-6.3Ra, meet the pressure vessel welding requirements.

3. Beveling angle is adjusted arbitrarily between 0°-60°.

4. 24V control box and 380V electrical box are designed separately.

5. The rear position of feed motor is favorable for narrow plate processing.

6. KQ-60S edge milling machine can process V/Y/K/X bevels of mild steel, stainless steel, manganese steel, high strength steel, titanium, nickel, aluminum alloy and other metal plates.

7. Widely used in welding and cutting manufacturing fields such as steel structure, pressure vessel, engineering machinery, machining shipbuilding, metallurgy, electric power tower, petrochemical industry, wind power and so on.